Our Manufacturing Facilities

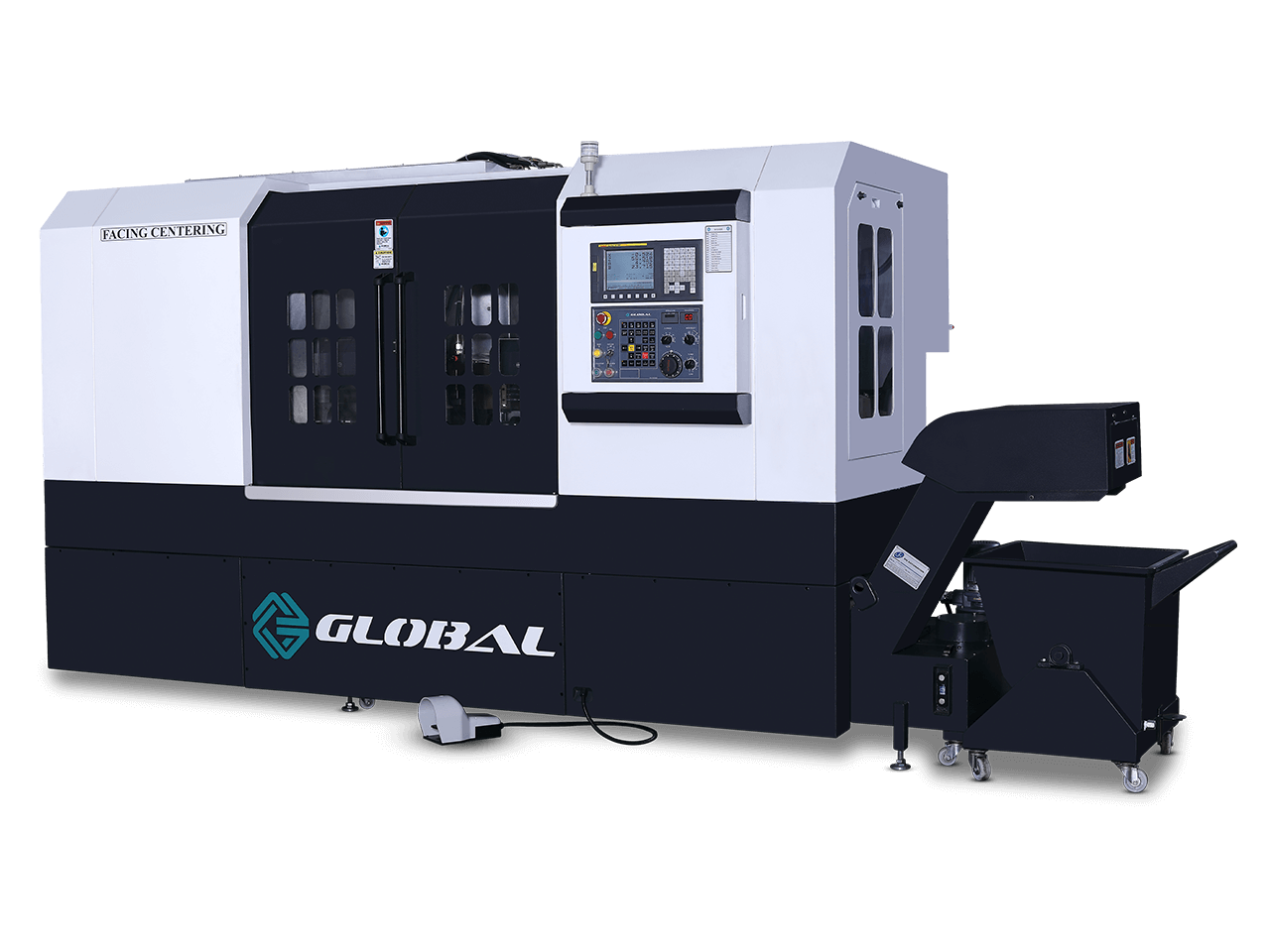

CNC Turning Center

Vertical Machining Center (VMC)

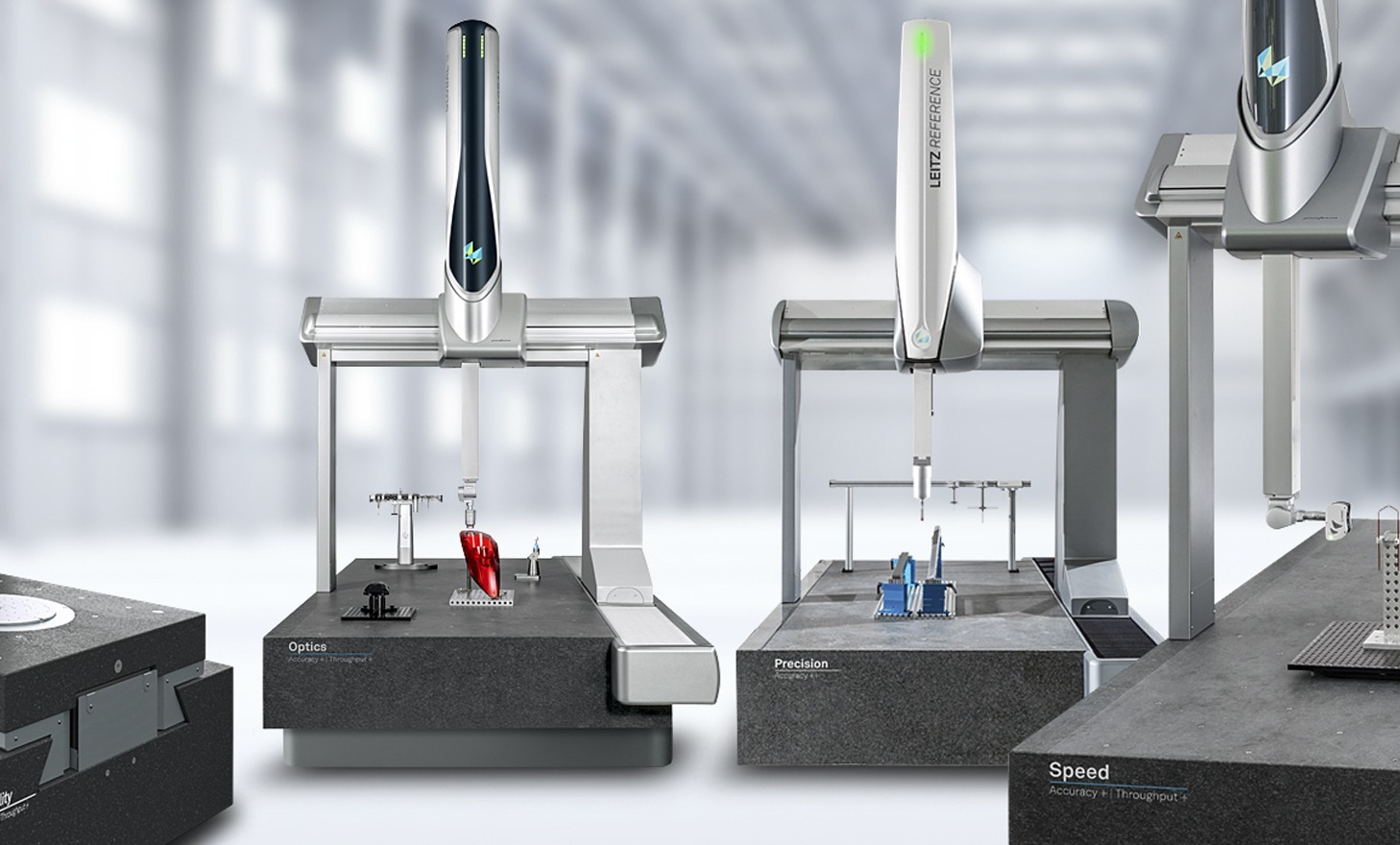

CMM

We are equipped to handle large and complex machining jobs, with a turning diameter up to 600 mm and turning length up to 1000 mm, ideal for heavy industries and critical component manufacturing.

Our expertise includes SG Iron, stainless steel (SS grades), and exotic materials like Inconel. We specialize in ACME threading and high-tolerance machining, making us a preferred partner for industries demanding precision.

Thanks to our use of the latest CAD/CAM and simulation software, and a team of expert design engineers, we can develop high-quality components in short turnaround times without compromising on quality.

We offer production scalability—be it low-volume batch manufacturing or high-volume mass production, our facilities and workflow are designed to deliver consistent quality at any scale.

We support 3D design, reverse engineering, and CAM programming to ensure our machining programs are optimized for performance, efficiency, and precision.

Every component undergoes rigorous inspection using advanced measuring instruments and quality assurance protocols, ensuring it meets exact specifications before delivery.

Up to 600 mm diameter and 1000 mm length for large jobs

Machining of SG Iron, Stainless Steel, Inconel, and more

Capable of ACME threading and other complex profiles

Supports both batch and mass production requirements

Fast prototyping with CAD/CAM tools and skilled engineers

Equipped with 3D design, reverse engineering, and CAM programming

Our modern warehouse is designed for organized storage, safe material handling, and streamlined dispatch. With dedicated inventory management systems, we ensure timely availability of raw materials and finished components, enabling smooth production flow and on-time deliveries to clients.