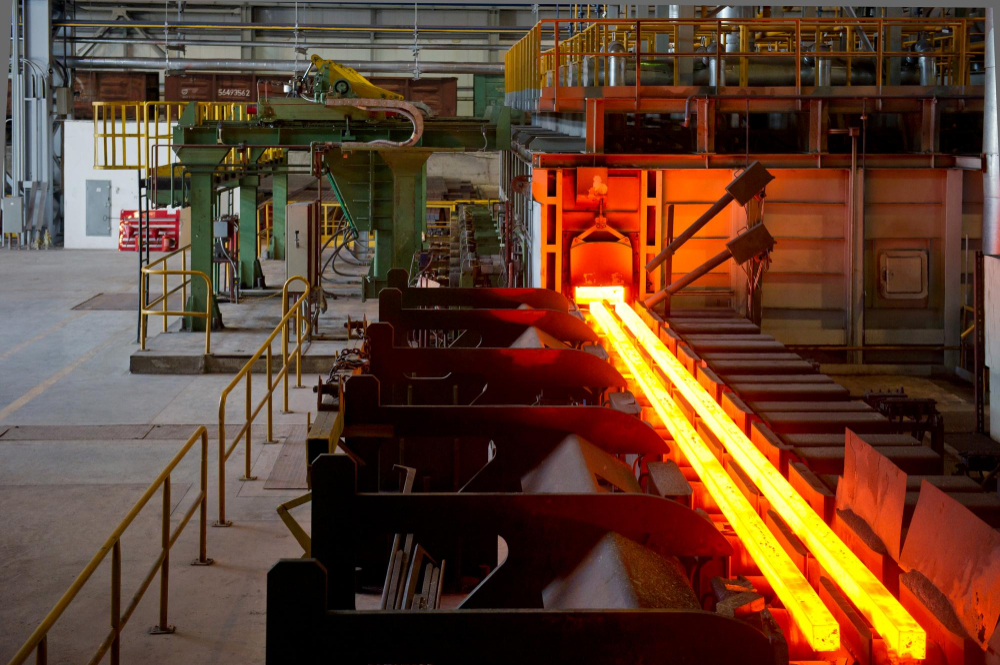

Castings for the energy sector

Steel castings for the energy sector

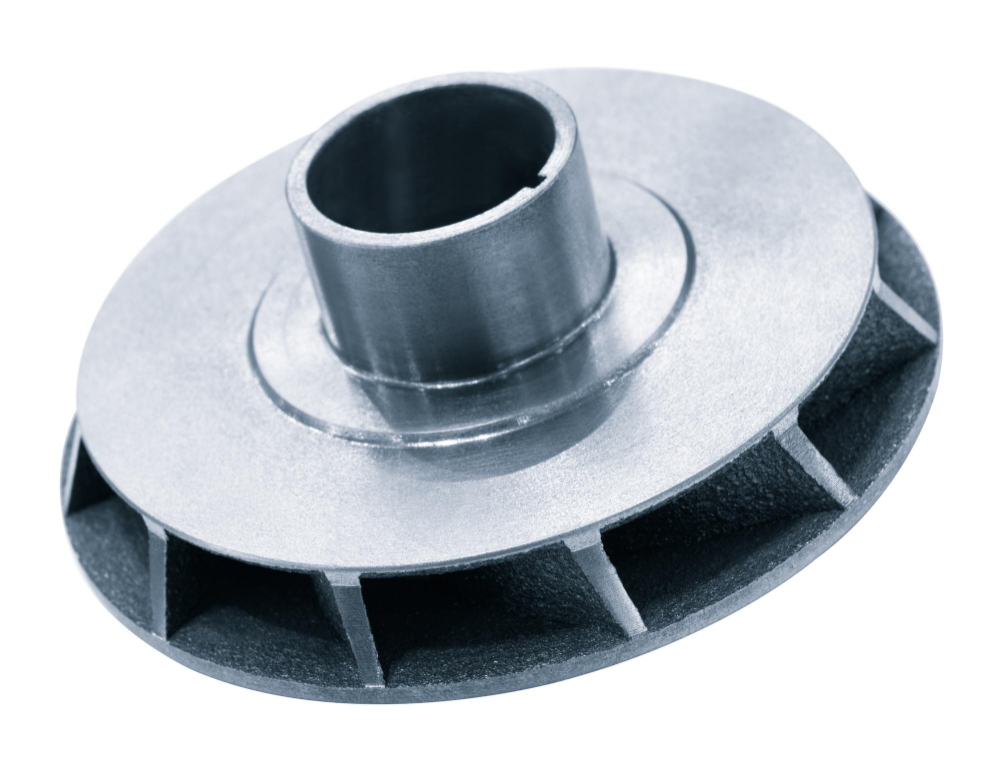

Castings for the machinery industry

Castings for for the machinery industry

Aerospace Components

Exontric Metal Works, founded in 2014, is a semi-automatic foundry with a monthly production capacity of 200 MT. We manufacture precision machined components ranging from 3 Kg to 30 Kg, supplying to leading domestic clients in India as well as international markets across Europe, USA, and China. Our product range includes farm equipment, off-road vehicles, heavy commercial vehicles, and a wide variety of engineering components and subassemblies.

Equipped with advanced facilities such as a spectrometer, microscope with image analyzer, and other modern testing instruments, Exontric Metal Works ensures every component meets the highest standards of quality, reliability, and performance. Our integrated processes allow us to consistently fulfill customer requirements while maintaining strict process control.

By producing high-quality castings in-house, we significantly reduce costs and lead times, offering clients a seamless and efficient supply chain. With a strong commitment to technology, innovation, and customer satisfaction, Exontric Metal Works continues to be a trusted partner for industries worldwide.

Lorem ipsum dolor amet, consecte tempor incididunt ut labore et dolore tumber tur adipisicing elit.

Lorem ipsum dolor amet, consecte tempor incididunt ut labore et dolore tumber tur adipisicing elit.

Lorem ipsum dolor amet, consecte tempor incididunt ut labore et dolore tumber tur adipisicing elit.

Lorem ipsum dolor amet, consecte tempor incididunt ut labore et dolore tumber tur adipisicing elit.

Lorem ipsum dolor amet, consecte tempor incididunt ut labore et dolore tumber tur adipisicing elit.

Lorem ipsum dolor amet, consecte tempor incididunt ut labore et dolore tumber tur adipisicing elit.

Welcome to the Pattern Shop Division! Our pattern shop is the heart of the foundry process, where we craft the blueprints for metal parts with precision and expertise. Let's explore the importance of the pattern shop and the materials we use:

Importance of the Pattern Shop

The pattern shop plays a crucial role in the foundry process by creating the moulds and cores necessary for casting metal parts. Here's a simplified overview of the process:

1. Design: Skilled patternmakers design the blueprint or pattern for the metal part based on specifications and requirements.

2. Material Selection: The appropriate material is selected based on factors such as durability, machinability, and thermal conductivity.

3. Pattern Creation: Patterns are crafted using various tools and techniques to ensure accuracy and precision.

4. Mould Making: The pattern is used to create moulds, which serve as templates for shaping molten metal during the casting process.

Core making is an essential process in casting, allowing for the creation of internal cavities or complex shapes within castings. Our expertise in traditional core making methods ensures high-quality, precise cores that meet industry standards. We specialize in adapting our processes to fit the specific needs of our clients, providing fully customized core solutions.

We utilize the following traditional core making techniques:

Processes we follow:

Hot Box: Fast (Thermal curing)

Cold Box: Fast (Room temperature with gaseous catalysts)

Shell: Rapid (Heat-assisted)

Heated core boxes for Hot Box and Shell Core making.

Gas generation and injection systems for Cold Box making.

Specialized core-making machinery for all processes.

Hot Box & Shell: Quick due to thermal curing

Cold Box: Slightly slower, chemical curing

Sand: We use high-quality, uniformly graded silica sand across all processes.

Binders: binder name.

Hot Box & Shell Core Making: Thermosetting resins like phenolic and furan.

Cold Box Core Making: Polyurethane, furan, or phenolic urethane binders.

Our melting facilities play a vital role in transforming solid metal into molten form, crucial for casting and shaping processes. Using high-temperature techniques, we ensure efficient melting with precise control over temperature and composition, guaranteeing high-quality production.

The Inductotherm Hybrid Furnace combines coreless induction and channel melting technologies, offering flexibility in alloy use and efficient large-scale aluminum casting.

Furnace Name: Inductotherm Hybrid Furnace

Furnace Type: Induction and Electric Arc Combination

Furnace Size: Configurable from 5 to 25 tons

Melting Capacity: Up to 25 tons per hour

Power: Ranges from 250 kW to 6,000 kW

Duration for Melting: 30 minutes to 2 hours

Casting Range: Suitable for various casting processes

Materials Used: Steel, aluminum, copper, and alloys

Spare Capacity: Typically 60% of total capacity

Used Capacity: Up to 80% for effective operations

Temperature Range: Up to 1,600°C

Dura-Line® induction melting furnaces are designed for rugged use, offering high-power density in a midsize package. Built with heavy cast refractory, stainless steel reinforcement, and copper power coils, they ensure durability and efficiency. These furnaces feature hydraulic or hoist tilting, single-trunnion action, and "nose-tilt" pouring. Ideal for efficient melting with budget-friendly options, they provide a wide range of capacities while ensuring structural integrity and easy maintenance.

01. Furnace Name: Inductotherm Dura-Line® Furnace

02. Furnace Type: Coreless Induction Furnace

03. Furnace Size: Available in various configurations to suit different operational needs

04. Melting Capacity: Up to 25 tons per furnace (depending on model)

05. Power: From 250 kW to 12,000 kW

06. Duration for Melting: 45 minutes to 3 hours, depen

The Tenova Consteel® EAF is engineered for high efficiency and reliability, boasting a melting capacity of 30 to 420 tons per hour. Operating at power levels of 10 MW to 180 MW, it achieves temperatures up to 1,800°C. The melting duration typically ranges from 45 to 90 minutes, with an operational capacity utilization of 85-90%. This furnace is versatile, processing various materials such as scrap metal and pig iron, making it an ideal choice for modern melt shops.

Casting Materials:

Compatible with iron, steel, and aluminum alloys.

Casting Range:

Additional Features:

Casting Materials:

Compatible with iron, steel, and aluminum alloys.

Casting Range:

A Sand Plant is essential in metal casting, managing sand preparation and ensuring the quality of cast products. Key components include the High-Speed Intensive Mixer (DISA) for optimal sand mixing, Sand Coolers to regulate temperature, and an Auto Sand Mix Control System to maintain consistency. These systems ensure the sand is properly conditioned for the molding process, enhancing casting precision and productivity, and improving the overall efficiency of metal foundries.

The DISAMIX is a next-generation bentonite-bonded foundry sand mixer engineered for high-speed, energy-efficient performance in green sand foundries. Designed to meet modern foundry needs, the DISAMIX

Specifications:

Model: S100

Capacity: 100t/h

Parameter: S100

Mixer Capacity: 100t/h

Batch Capacity: 3000 kg

Installed Power: 160 kW

Water Consumption: 20 l/min

Mixer Height: 2970 mm

Net Weight: 17 Tonnes

Fast and precise pre-water dosing

fast and complete mixing with short cycle times.

advanced data-driven process control, real-time production monitoring

Automates sand moisture control and ensures consistent quality

Pneumatic bond injection

technology employed for optimal mixing performance.

Fettling is the crucial process of cleaning and finishing castings to remove excess material and ensure compliance with specifications. Common equipment in a fettling shop includes shot blasting machines that use high-velocity abrasives for thorough cleaning, grinding machines for refining surface finishes and dimensions, robotic fettling systems that automate grinding and polishing tasks for improved productivity, and vibratory finishing machines that effectively polish and deburr castings.

These machines play a vital role in maintaining quality control in foundries, enhancing the overall efficiency of the production process.

The DT Continuous Through-Feed Tumblast Machine is designed for efficient and cost-effective blast cleaning of castings and forgings in foundries. Utilizing advanced wheelblast technology, this machine automates the cleaning process, ensuring optimal results while minimizing manual handling and operational costs. Technical Specifications: Materials Used: Abrasive materials (e.g., steel shots, grits)